How Plastic Fabrication with Waterjets is Revolutionizing Modern Manufacturing

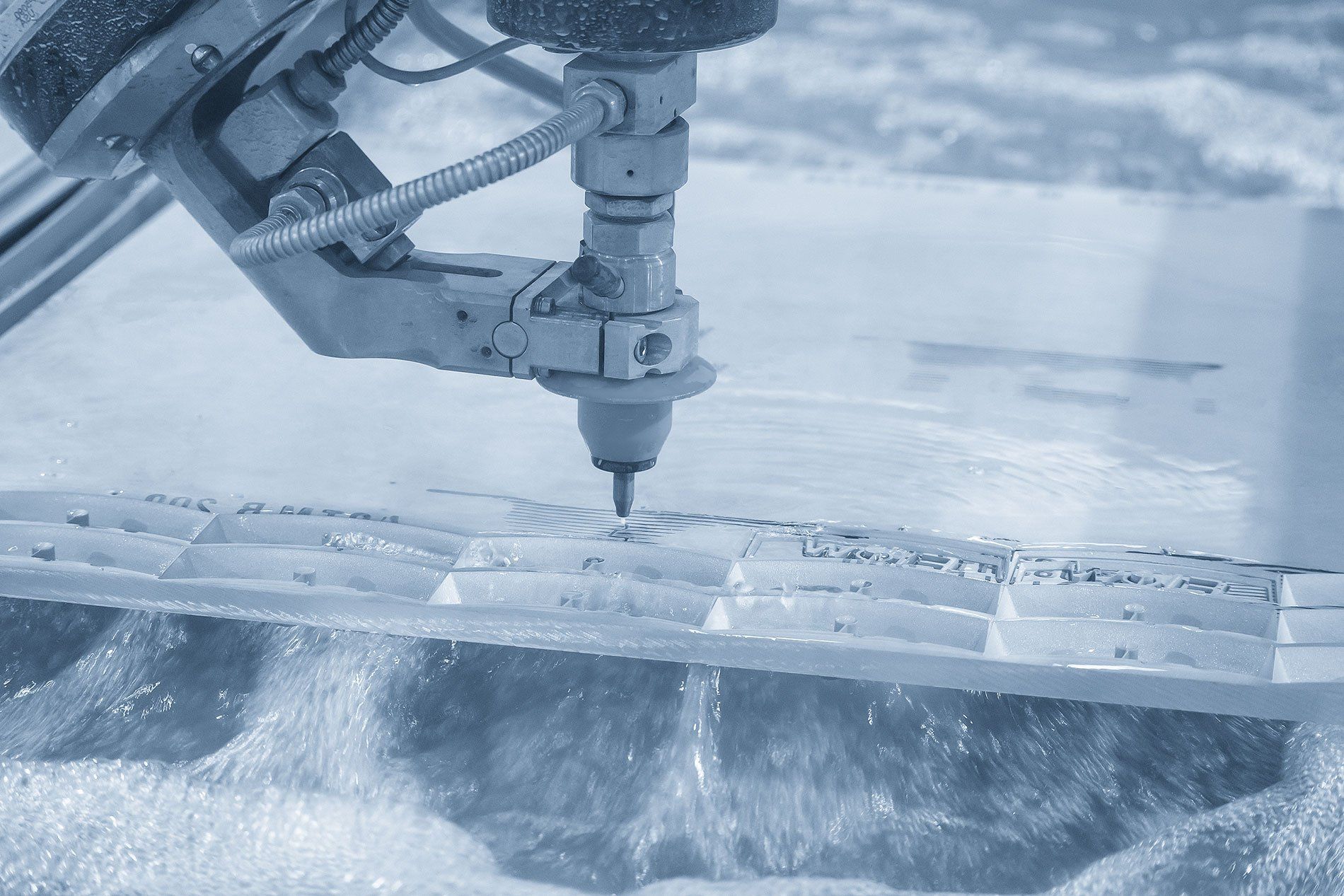

Waterjet cutting is changing the game for plastic fabrication. By harnessing ultra-high-pressure streams of water, manufacturers can achieve incredibly precise cuts without heat distortion or toxic emissions. This technology is opening up new possibilities for design, efficiency, and sustainability across many industries.

Why Waterjet Cutting Stands Out

Waterjet systems, guided by advanced CNC controls, enable the creation of detailed shapes and smooth edges in a wide range of plastics, including acrylic, polycarbonate, HDPE, PVC, and more. Unlike traditional cutting methods, waterjets don’t cause melting or release harmful fumes, making the process clean and eco-friendly.

Manufacturers can cut intricate parts with tolerances as tight as ±0.003 inches, and often skip secondary finishing steps thanks to the clean, polished edges. Because waterjets can adapt to different thicknesses and materials, they offer significant flexibility for both prototyping and full production runs.

Environmental and Efficiency Benefits

Waterjet cutting produces minimal waste due to its precise, narrow cuts. With no need for harmful chemicals or additional cooling fluids, it’s a safer option for both workers and the environment. Plus, the clean scrap generated can typically be recycled, further reducing environmental impact.

Transforming Multiple Industries

Industries like aerospace, medical devices, automotive, and electronics rely on waterjet-cut plastics for their accuracy, efficiency, and adaptability. Waterjet technology helps create complex components quickly—supporting innovation and reducing manufacturing costs.

Midland Waterjet: Experts in Precision

Midland Waterjet leads the way in waterjet plastic fabrication, serving businesses across West Texas and beyond. Their experience with various plastics and commitment to quality ensure clients get the best results, whether for prototypes or large production orders.

Ready to Learn More?

Discover how Midland Waterjet’s advanced waterjet cutting services can take your next project to the next level with precision and efficiency. Our cutting-edge technology ensures clean, accurate cuts for a variety of materials, including plastics, making them the ideal choice for your plastic fabrication needs. Whether you're working on a small-scale prototype or a large production run, their experienced team is ready to help. Contact us today to explore the possibilities and see how their services can bring your vision to life.