The Role of Waterjet Cutting in Creating Custom Steel Signs

Creating a sign that stands out requires precision, durability, and a clean finish. For businesses looking for high-quality signage, the manufacturing process is just as important as the design itself. Waterjet cutting has become a prominent method for fabricating custom steel signs, offering a level of detail and quality that other methods can't always match. This process allows for intricate designs and smooth edges, ensuring that the final product accurately represents a company's brand.

This post will explain the role of waterjet cutting in creating custom steel signs. We will cover how the technology works, the benefits it offers for sign fabrication, and how it compares to other cutting methods. Understanding this process can help you make an informed decision when commissioning a durable and visually appealing sign for your business.

What is Waterjet Cutting?

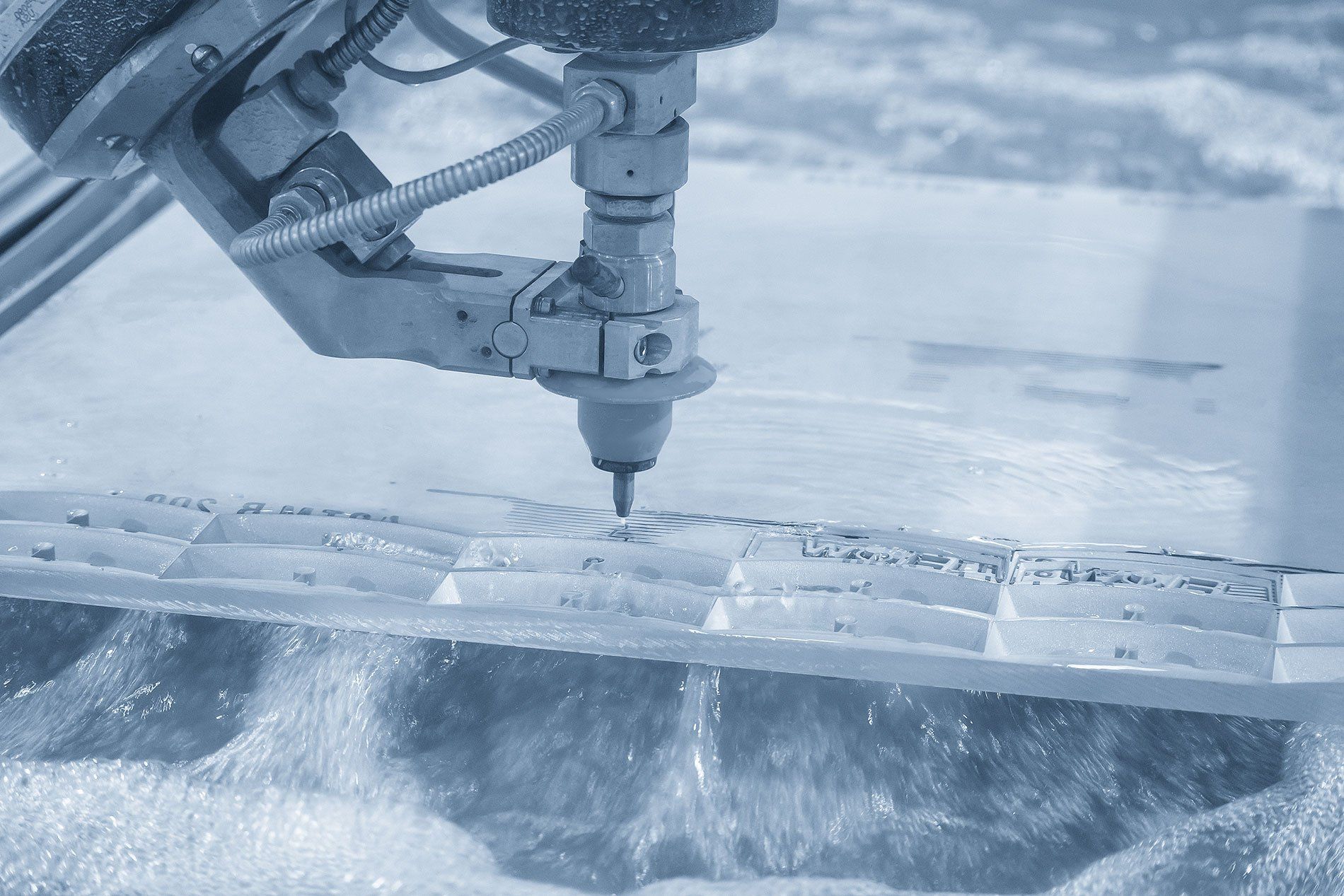

Waterjet cutting is a fabrication process that uses a high-pressure stream of water to cut through a wide variety of materials. To cut harder materials like steel, an abrasive substance, such as garnet, is mixed into the water stream. This mixture is then forced through a small nozzle at a very high velocity, creating a powerful cutting tool that can slice through metal with remarkable accuracy.

The entire process is controlled by a computer, which follows a digital design file. This allows for the creation of complex shapes and intricate patterns that would be difficult or impossible to achieve with traditional cutting tools. Because it is a cold-cutting process, it does not generate heat, which prevents the material from warping or having its structural integrity compromised.

Benefits of Using Waterjet Cutting for Steel Signs

When it comes to creating custom steel signs, the method used to cut the material plays a significant role in the quality of the final product. Waterjet cutting offers several distinct advantages that make it an ideal choice for sign fabrication.

Precision and Intricate Designs

Waterjet cutting is guided by computer-aided design (CAD) software, which allows for an extremely high level of precision. This technology can produce complex fonts, detailed logos, and elaborate patterns with clean, sharp edges. The fine cutting stream enables the creation of detailed work without sacrificing accuracy, ensuring that your sign matches your design specifications exactly.

No Heat-Affected Zone (HAZ)

Unlike plasma or laser cutting, waterjet cutting is a cold-cutting process. It does not generate heat, which means there is no heat-affected zone (HAZ) on the material. This is particularly important for steel signs, as heat can cause discoloration, warping, and changes to the metal's structural properties. With no thermal stress, the steel maintains its original strength and appearance, resulting in a more durable and aesthetically pleasing sign.

Smooth, High-Quality Finish

The waterjet cutting process produces a smooth, sandblasted-like finish along the cut edge, which often eliminates the need for secondary finishing processes like grinding or polishing. This not only saves time and reduces costs but also ensures a consistently high-quality edge on every part of the sign. The result is a clean and professional look that enhances the overall visual effect of your signage.

Material Versatility

While this post focuses on steel, waterjet technology is capable of cutting a vast range of materials without requiring a change in setup. This includes different types of metals like aluminum and copper, as well as plastics, wood, and stone. This versatility means that steel can be combined with other materials in a single sign design, allowing for more creative and unique results. For example, steel lettering can be inlaid into a wooden or plastic background to create a striking industrial effect.

How Waterjet Cutting Compares to Other Methods

While other cutting methods like laser and plasma cutting are also used in metal fabrication, waterjet cutting offers unique advantages for custom signage.

- Laser Cutting - Laser cutting uses a high-powered laser to melt, burn, or vaporize the material. While it is very precise, it creates a heat-affected zone that can alter the properties of the steel and may require secondary finishing. It is also limited by the thickness of the material it can cut.

- Plasma Cutting - Plasma cutting uses a jet of hot plasma to cut through electrically conductive materials. It is faster than waterjet cutting but less precise and creates a significant heat-affected zone. The edges produced by plasma cutting are often rough and require additional finishing.

For custom steel signs where precision, edge quality, and material integrity are priorities, waterjet cutting is often the superior choice.

Custom Steel Signs at Midland Waterjet

At Midland Waterjet, we specialize in creating custom steel signs for businesses throughout Midland, Odessa, Abilene, and Lubbock, TX; as well as the surrounding areas. Using advanced waterjet cutting technology, we can transform your company’s logo and branding into a high-quality and durable sign that makes a lasting impression. Our process ensures that every detail of your design is captured with precision.

We are equipped to handle projects of all sizes and complexities, working with you to bring your vision to life. Whether you need a striking exterior sign to attract customers or a professional lobby sign, our fabrication services are tailored to meet your specific needs. We are committed to delivering a finished product that reflects the quality and professionalism of your brand. To learn more about our custom steel sign services or to discuss your project,

contact us today!